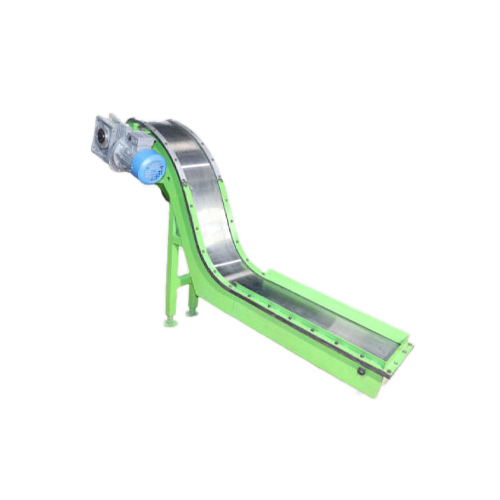

Industrial Magnetic Type Conveyor

Industrial Magnetic Type Conveyor Specification

- Power Source

- Electric

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Standard

- Belt Conveyor

- Flat Belt

- Product Type

- Industrial Magnetic Type Conveyor

- Color

- Green

- Resistant Feature

- Heat Resistant

- Voltage

- 220-440 Volt (v)

- Warranty

- Yes

Industrial Magnetic Type Conveyor Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial Magnetic Type Conveyor

An Industrial Magnetic Type Conveyor is a specialized conveyor system that utilizes magnetic forces to transport ferrous materials in various industrial applications. It is designed to handle ferromagnetic materials such as iron, steel, and other magnetic components. These conveyors are commonly used in industries such as recycling, metalworking, mining, and automotive manufacturing. They are ideal for transporting ferrous materials like metal chips, scrap, parts, and powders. Industrial Magnetic Type Conveyor offer an efficient and reliable solution for transporting ferrous materials in various industries. Their ability to attract and securely hold ferromagnetic materials simplifies material handling processes and enhances productivity.

| Model | DSLC 6M |

|---|---|

| Pitch | 15.875 mm |

| Application | Hobbing, gear cutting, shaving |

| Chip Carrying Capacity | As per application |

| Design | Customize |

| Material | Ferrous material |

| Type of chip | Fines / swarf / sludge / small / broken chips Small parts (screws, bolts, etc) |

Advanced Material Handling Solution

This magnetic type conveyor offers robust performance for the transportation of metal parts and other materials within industrial facilities. The combination of a flat belt and magnetic system ensures secure and steady movement, enhancing both productivity and safety. Its heat resistance and stainless steel body make it suitable for demanding environments.

Electric Powered Efficiency

Powered by a reliable electric source between 220 and 440 volts, the conveyor is designed for continual operation in manufacturing plants. The flat belt surface provides straightforward loading and unloading, accommodating standard industrial requirements effectively.

FAQs of Industrial Magnetic Type Conveyor:

Q: How does the magnetic type conveyor aid in industrial material handling?

A: The conveyor utilizes magnetic technology to securely transport ferrous materials across its flat belt, preventing product losses and facilitating seamless movement in production lines.Q: What are the benefits of using a heat-resistant, stainless steel conveyor belt?

A: The heat-resistant flat belt made of stainless steel is ideal for environments where high temperatures are present, reducing risks of damage and ensuring longevity while maintaining structural integrity.Q: When is it recommended to use this magnetic conveyor in industrial settings?

A: It is best used whenever consistent transportation of metal parts or heat-sensitive items is required, particularly in manufacturing, assembly, or processing facilities.Q: Where can this magnetic type conveyor be installed?

A: This conveyor is suited for installation in industrial plants such as factories, assembly units, and processing facilities where reliable material handling is critical.Q: What is the process for installation and commissioning?

A: The conveyor is delivered in standard sizes for ease of installation. Professional guidance from the manufacturer ensures efficient setup and commissioning within industrial environments.Q: How is this conveyor powered and what voltages does it support?

A: It operates on an electric power source, compatible with standard industrial voltages ranging from 220 to 440 volts.Q: What warranty and after-sales support are provided?

A: The conveyor comes with a warranty, and customers can rely on the manufacturers or suppliers after-sales support for maintenance, troubleshooting, and spare parts provision.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese